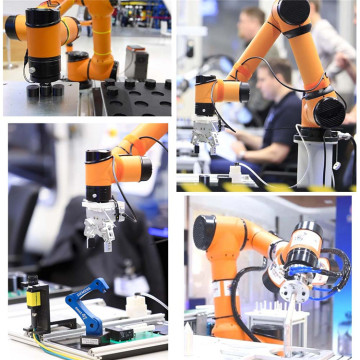

CNC forging manipulator industrial robotic arm

Product Description

CNC forging manipulator industrial robotic arm

The forging manipulator is driven by a full servo motor with fast response speed and high accuracy. The maximum load is 8KG, and the maximum arm span can reach 1500mm. Realize a wide range of movements with a compact structure, flexible and precise movement.

Purpose: In industrial production, it can replace people to do certain monotonous, frequent and repetitive long-term operations, or operations in dangerous and harsh environments, such as stamping machines, pressure casting, heat treatment, welding, painting, plastic product forming , Mechanical processing and simple assembly processes, as well as in the atomic energy industry and other sectors, complete the handling or process operations of hazardous materials to the human body, and complete the upper and lower processes perfectly.

Composition of forging manipulator

Actuating mechanism: It includes the claws, wrists, arms, columns and walking mechanism.

1. Claw

It is the part that clamps the workpiece, similar to the clamp of the forging manipulator. The form of the clamping claw is similar to that of a human finger, with clamping and unclamping actions.

2. Wrist

It is a part that connects the claw and the arm, supports the claw, and adjusts the position of the clamped workpiece in space. The wrist generally has three movements of pitching, swinging left and right and rotating around its own axis. Some manipulators do not have a wrist.

3. Arm

It is a component used to support the clamped workpiece, claws and wrist. It can move the workpiece from one position to another in space according to a certain trajectory. Generally, the arm has movements such as forward and backward extension, up and down lifting, left and right rotation, and up and down swing.

4. Column

It is the part that supports the arm. The column of the manipulator is usually fixed, sometimes due to need, the column can also be designed to be movable, called a movable column.

5. Walking mechanism

When the manipulator needs to complete a relatively long-distance operation, a walking mechanism such as rollers and guide rails can be installed on the base to realize the movement of the whole machine.

Intelligence

1. Vision systems can be integrated into controller.

2. Software system based on cloud platform management that realizes remote maintenance, fault diagnosis and online upgrading of firmware.

3. This research robot platform is used widely around the world in corporate research labs and for academic robotics research.

Modular Design

1. Robot can be configured to have between four and seven degrees of freedom to meet user requirement.

2. Joint length can be customized to longer or shorter links.

In addition to the Robot Arm Machine, our company also has many products, such as Soldering Fume Extractor, Solder Paste Dispenser, Pneumatic Hand-held Screw Feeder, Automatic Screw Feeder . If you need these products, you can contact us, we will reply to you as soon as possible.

Technical Specifications

| Controlled Axed DoF | 6 axes (J1, J2, J3, J4, J5, J6) J7max |

| Reach | 924 mm |

| Working Range | 880 mm |

| Payload | 5kg |

| Weight | 24kg |

| Footprint | 172 mm diameter |

| Collabortative Operation | Safety monitored stop, speed and separation monitoring, hand guid operation, power and force limiting design. |

| Certifications | ISO 10218-1:2011, EN 60204-1:2006 +A1:2009 ISO 12100:2010, ISO 13849-1:2008, CE |

| Repeatability | ±0.02mm |

| Linear Velocity | 2.8 m/s adjustable |

| Power Consumption | 200 watts typical application |

| Materials | Aluminum, Steel, Plastic |

| Ambient Humidity | Normal 75% RH or less without frost, or dew, 85% RH short term |

| Ambient Temperature | 0 to 45 degrees Celsius |

| IP Classification of Robot | IP 54 |

| Programing | Teach Pendant with user interface, guide to teach, ROS compatibility through an API, Lua, Python. |

| Communication | CAN Bus |

| Motor Type | Harmonic drive 48 Volt |

| Installation Orientation | Any celling, Floor, Wall |

| Axis | Working Range | MAximun Speed | Max Joint Moments |

| J1 axis rotation base | (+/-)175° | 150°/sec | 207Nm |

| J2 axis rotation shoulder | (+/-)175° | 150°/sec | 207Nm |

| J3 axis rotation elbow | (+/-)175° | 150°/sec | 207Nm |

| J4 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

| J5 axis wrist swing | (+/-)175° | 180°/sec | 34Nm |

| J6 axis wrist rotation | (+/-)175° | 180°/sec | 34Nm |

| Dimensions (LxWxH) | 683x220x622 mm | I/O Ports | User I/O | Safety I/O | |

| Weight | 20kg | Digital in | 16 | 16 | |

| Cabling | 5m | Digital Out | 16 | 16 | |

| Colour | Black | Analog in | 4 | - | |

| Communication | TCP/IP, Modbus-RTU/TCP | Analog out | 4 | - | |

| Power supply | 100-240 VAC, 50-60Hz | Power input | 24 Volts | ||

| IP Classification | IP54 | Power output | 3A | ||

Product Categories : Robot Arm Machine > Kingsom New Arrival Industrial Forging Manipulator Robot Arm